-

Мобильная дробилка

- небольшая каменная дробилка масштаб Мельница Цена

- мельница шаровой мельнице галерея

- спиральный желоб для хрома

- кварцевые шаровые мельницы видео

- дробилка роторная модель 1214

- механизм угольной мельницы на цементном заводе в Мальте

- сепаратор цемента системы помола

- В Южной Африке горных поставщиков

- выбор мощности двигателя для шаровой мельницы

- Разница между мельницы и дробилки

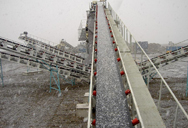

- континентальный ленточный конвейер

- карьер шлак дробилка завод для Аджмер

- шаровая мельница для гипса тонн

- плита для камнедробилки

- Lafarge бетон ОАЭ золотой руды дробилка

- Шаровая мельница с высоким качеством

- отзывы о садовом измельчителе bosch axt 2000 rapid

- б щековая дробилка Кун Кун для продажи в uk дробилка Китай

- завод изготовитель дробилки skorpion r и e

- щековая дробилка из хайдарабада

<моечное оборудование для промывки песка и ще я прайс

Щековые дробилки: Назначение ...

Щековая дробилка – это промышленный измельчитель. Предназначен для переработки кусков природной или каменной породы, размером 160 – 20 см, в

Read More

Щековая дробилка — Википедия

Щековая дробилка является универсальной машиной для дробления материалов. Применяется на горных породах любой прочности, на шлаках,

Read More

Принцип действия щековой дробилки ...

Щековая дробилка – специализированное оборудование, которое широко используется в горно-перерабатывающей промышленности в первичном цикле

Read More

Щековые дробилки: принцип работы и ...

2020.2.14 Принцип работы щековой дробилки. Общая информация про устройство щековой дробилки, обзор схем и чертежей. Подробное описание

Read More

Щековые дробилки Рудпром

Вот схема щековой дробилки с простым качением щеки. Клиновидная камера дробления образуется одной неподвижной щекой и одной качающейся, которая с

Read More

Дробилка - что это, виды, схема работы ...

Для измельчения высокопрочных материалов крупной и средней фракций выбирают щековые измельчители. Их чего состоит щековая дробилка: основной рабочий

Read More

Щековая дробилка для угля Хайдарабад

Высокоэффективная конусная дробилка по серии cs 1. Применяет новую технологию по камере с рациональными темпами и тактами, получает более действенную силу

Read More

Щековые Дробилки - Дробильно ...

Щековые дробилки измельчают большие куски пород и руд путем сжатия. Механическое давление создается при помощи двух щек, одна и которых

Read More

Щековая дробилка: устройство, принцип ...

2024.5.27 Щековая дробилка — это машина, способная справиться с этой задачей, обеспечивая высокий уровень дробления твёрдых пород. Принцип ее

Read More

Щековая дробилка: Работа, устройство и ...

2023.12.11 От этого же зависит и вид дробления, который может быть крупным, средним или мелким. Например, дробилка для руды щековая предназначается для измельчения кусков горных пород в 3 раза, не более.

Read More

sbm/sbm шаровые мельницы с поставщиком из ...

Contribute to jgw2023/sbm development by creating an account on GitHub.

Read More

Щековая дробилка принцип работы ...

Как работает щековая дробилка Постоянное сопряжение между распорными плитами, шатуном и подвижной щекой поддерживается благодаря применению замыкающего механизма, который состоит

Read More

Щековые дробилки Сравнить цены и ...

Щековая дробилка бензиновый двигатель 13 л.с. для строительных отходов (камень, керпич, бетон) bizon-300. В ... Показано 1 - 29 товаров из 800+

Read More

Устройство щековых дробилок - виды и ...

Принцип действия и виды щелковой дробилки: схема и устройство щековой дробилки. Полное описание конструкции щелковой дробилки.

Read More

Дробилка щековая ДЛЩ 80х150А ...

Дробилка лабораторная щековая ДЛЩ 80х150 А Назначение Дробилки щековой ДЛЩ 80х150А лабораторной: Для мелкого дробления горных пород и других материалов, предел прочности которых не превышает 250 Мпа (4000 кгс/см2).

Read More

Щековые дробилки: виды, конструктивные ...

2013.3.22 Щековая дробилка – универсальное оборудование, которое активно используется для измельчения твердых материалов и выдает готовое сырье с размерами от 10 до 1500 миллиметров.

Read More

Щековая дробилка Essa JC 2501 FLSmidth ...

Щековая дробилка Essa JC 2501 FLSmidth. Производитель: ... Комплекты активаторов рассева из оксида алюминия Ø10 мм в ...

Read More

Щековая дробилка с делителем проб Rocklabs ...

Дробилка щековая ДЩ 60х100 лабораторная; Дробилка щековая ЩД 10; Щековая дробилка Rocklabs BOYD Elite (SCOTT) Истиратель дисковый ИД-175 лабораторный (настольный) Делитель проб ДП 10 желобчатый

Read More

Рабочие элементы щековых дробилок ...

На рис. 2 представлена щековая дробилка с верхним подвесом и простым качанием подвижной щеки (см. схему рис. 1, а), передняя стенка щековой дробилки условно снята. Рис. 2.

Read More

Щековая дробилка ООО ...

Щековая дробилка – современная машина, используемая для дробления различных материалов: камня, руды, угля, щебня и многих других. Она состоит из двух челюстей: ...

Read More

поставщика шаровых мельниц из ...

Щековая дробилка из Хайдарабада Щековая дробилка PE chinadrobilki ru Щековая дробилка pe компании предназначена для так дроблёное сырьё выходит из appliions из Поставщики шаровых мельниц в ...

Read More

Щековая дробилка: устройство, принцип ...

2016.12.4 К примеру, если используется щековая дробилка СМ 741, ... из-за малых размеров, обычно очень просто и легко собираются и разбираются.

Read More

Дробилка щековая ЩД 15 лабораторная ...

Щековая дробилка ЩД 15 является продолжением линейки щековых дробилок ЩД 6М и ЩД 10М. ... стенок корпуса в зоне дробления защищена футеровочными бронями из износостойкой стали.

Read More

Щековые дробилки: принцип работы и ...

2020.2.14 Наиболее распространена сейчас щековая дробилка со сложным качанием (рис. 5) . Она отличается тем, что верхняя часть подвижной щеки соединена с эксцентриковым валом и описывает окружности.

Read More

Щековые дробилки « Тульские Машины ...

Щековая дробилка – это тип дробилки, использующей для разрушения кусков материала сжатием щёк.. Щековая дробилка является универсальной машиной для дробления материалов. Применяется на горных породах любой ...

Read More

Производство дробильно ...

Статья “Щековая дробилка” Производство и продажа дробильно-сортировочных комплексов ДРОБИЛЬНОЕ ОБОРУДОВАНИЕ – мощные установки, предназначенные для измельчения твердых материалов, относятся к дробильным ...

Read More

Дробилка молотковая, валковая, щековая ...

Понятно, что дробилка - одна из необходимых составляющих дробильно-сортировочного комплекса.С помощью дробилки выполняют измельчение всевозможных твердых материалов: от железобетонного лома до камня из карьера.

Read More

Щековая дробилка: принцип работы и ...

2024.3.29 Щековая дробилка — одно из старейших устройств для измельчения твердых материалов. Ее прообразы в виде каменных жерновов и ступок использовались людьми издревле.

Read More

Компания HOFTEC - Официальный дилер Sandvik

Щековая дробилка . Одной из разновидностей дробилок, которые с успехом выпускаются компанией Sandvik на протяжении почти 150 лет, является щековая дробилка.

Read More

ЩЕКОВАЯ ДРОБИЛКА Tashtek

Щековые дробилки являются одними из самых важных дробильных устройств, которые обычно используются в шахтах в качестве первичных дробилок, ... ЩЕКОВАЯ ДРОБИЛКА

Read More

Щековая дробилка (устройство и принцип ...

2015.4.11 Предлагаем вашему вниманию ролик подготовленный компанией zenith, которая является одним из ведущих ...

Read More

Щековая дробилка: устройство, принцип ...

2024.5.27 Давайте рассмотрим виды щековых дробилок, каждый из которых имеет свои уникальные характеристики и области применения. Щековая дробилка с простым движением щеки.

Read More

Щековая дробилка СМД-108 - технические ...

2023.1.7 Щековая дробилка СМД 108 часто используется для дробления неметаллов и руд. Это универсальный механизм, который дробит камни любой твердости: гранит, базальт, известняк, песчаник и другие породы.

Read More

Дробилка щековая ДЩ 120х200 — Дробтехника

Щековая дробилка ДЩ 120х200 — устройство и принцип работы: Дробилка ДЩ 120х200 состоит из установленного на раме корпуса, к которому крепятся загрузочная и разгрузочная воронки.

Read More

Щековая дробилка

Щековая дробилка состоит из станины, частью которой является неподвижная щека, вала с подвешенной подвижной щекой, приводного механизма и устройства для регулирования органами являются неподвижная и подвижная щеки.

Read More

Дробилка щековая ДЩ 80х150 лабораторная ...

Дробилка щековая лабораторная ДЩ 80х150. ... Дробилка ДЩ 80х150 состоит из установленного на раме корпуса, к которому крепятся загрузочная и разгрузочная воронки.

Read More

Щековая дробилка - это ... определение ...

Что такое Щековая дробилка? Щековая дробилка — это аппарат для крупного дробления, где материал разрушается между двумя металлическими плитами (щеками) раздавливанием, раскалыванием и изгибом. Одна из плит ...

Read More

шаровые мельницы поставщик из ...

2017.11.8 ГЛАВНАЯ / шаровые мельницы поставщик из хайдарабада. ... на продажу каменная дробилка завод 300 500 т ч т ч каменные дробилки из 250 400 щековая дробилка для продажи,100 т ч Используемая ...

Read More

Щековая дробилка - Металлообработка ...

Щековая дробилка. Сверхмощная литая конструкция из спецстали выдерживает нагрузку в 3 раза выше, чем у обычных аналогов. Эффективность: От 50 до 120 т/ ...

Read More