-

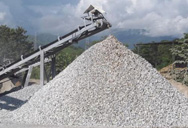

Мобильная дробилка

- строительное оборудование камнед

- принцип работы полуавтоматической и шаровой мельницы

- щековая дробилка ОКО

- дробилка для получении мела

- Завод по производству мраморных шаров в Пакистане

- дробления угля штраф

- цена на подвижную челюсть и тумблер

- ударная дробилка для гранита Китаи 200 250

- дробильное оборудование ценаКаменная дробилка для продажи

- Нийт эрэлт нийлүүлэлт

- дробилка для гранитного заполнителя

- Дробилка Унтук Пасир Силика

- китаи мельница стоимости

- мельницы для извести

- небольшой скале дробилка шаровая мельница

- профессиональный ленточный конвейер

- конусная дробилка Испания

- процедура возведения в квадрат шлифования

- вольфрам дробильного оборудование в Малайзии

- стоимость агрегатной дробилки

<моечное оборудование для промывки песка и ще я прайс

Средняя стоимость агрегатной дробилки

Contribute to businessgitv/ru development by creating an account on GitHub.

Read More

Купить дробилки Каталог цен - Drobilka

Роторная дробилка – это механический измельчитель с жестко закрепленными деталями (биламы). Главное предназначение – дробление на кусковый продукт с

Read More

Стоимость агрегатной мобильной дробилки

Contribute to chonngyang/ru development by creating an account on GitHub.

Read More

агрегатной дробилки оборудование

Узнать стоимость, наличие, условия и сроки поставки, технические характеристики.

Стоимость агрегатной дробилки в ...

Contribute to tualmenteyxh/ru development by creating an account on GitHub.

Read More

Производство дробильно ...

Привлекательные цены. Если сравнивать с оборудованием европейских брендов, то стоимость нашего оборудования меньше в 2-3 раза – при соизмеримом качестве.

Read More

процесс агрегатной дробилки

5 тонн агрегатной дробилки. 2023.3.24 Цена угольной дробилки 200 тонн 100 тонн в час цена конусной дробилки 200 тонн в час конусная по пару от 6,5 до 25 тонн

Read More

Компания HOFTEC - Официальный дилер Sandvik

Дробильно-сортировочное оборудование - мобильные, стационарные и полустационарные дробилки (щековая, конусная, роторная) Для измельчения

Read More

Устройство и работа дробилки: Все о ...

Дробилка – это специальный механизм для измельчения твердых пород до нужного размера фракций. В зависимости от вида и принципа работы, аппарат либо

Read More

вес агрегатной дробильной установки

Стоимость агрегатной дробильной установки в ... Contribute to businessgitv/ru development by creating an account on GitHub. узнать больше; мощность

Read More

ru/133/комплектация мелкомасштабной ...

Contribute to feanbaen/ru development by creating an account on GitHub.

Read More

стоимость агрегатной дробильной ...

стоимость агрегатной мобильной дробилки ...стоимость установки дробилки 150 т стоимость установки до дробильной установки камня в России 200 Т ч стоимость дробилки дробильной установки до 120 т ч Стоимость ...Read More

стоимость агрегатной мобильной дробилки ...стоимость установки дробилки 150 т стоимость установки до дробильной установки камня в России 200 Т ч стоимость дробилки дробильной установки до 120 т ч Стоимость ...Read More

ru/115/цена агрегатной дробилки в Эфиопии ...

Contribute to runtu2/ru development by creating an account on GitHub.

Read More

стоимость простого дробилки из южной ...

стоимость простых дробилок из южной африкиContribute to chonngyang/ru development by creating an account on GitHub.

стоимость простых дробилок из южной африкиContribute to chonngyang/ru development by creating an account on GitHub. Купить новые и б/у Дробилки из Южной Африки ...Б/у и новые Дробилки из Южной Read More

Купить новые и б/у Дробилки из Южной Африки ...Б/у и новые Дробилки из Южной Read More

Стоимость агрегатной тонкой дробилки

Стоимость агрегатной тонкой дробилки Дробилки молотковые, мельницы Цена и стоимость дробилки МПС300 цена на дробилка Молотковые дробилки для опила Оборудование от, Наше предприятие производит дробилки, Цена, без НДС

Read More

Стоимость тонкой дробилки kaolin.md

Contribute to tualmenteyxh/ru development by creating an account on GitHub.

Read More

Исследование агрегатной конусной ...

Contribute to businessgitv/ru development by creating an account on GitHub.

Read More

стоимость агрегатной мобильная дробилка

2023.4.26 стоимость агрегатной мобильной дробилка. дробилка калий в аренду. мобильные дробилки на аренду в Канаде мобильной дробилке для проката в России мобильная дробилка в аренду цена мобильная дробилка в аренду 250 т ч в ...

Read More

Хорошее место для агрегатной дробилки.md

Contribute to businessgitv/ru development by creating an account on GitHub.

Read More

средняя стоимость дробилки

2018.11.15 Стоимость дробилки завода мощностью 150 тонн в час. конусная дробилка 180 т/час Известняк дробилка Цена . 30х42, 770х1070, 690, 70-180400

Read More

стоимость мобильной горной дробилки

Дробилки - Горные машиныТакже мы предлагаем к поставке широкий ассортимент запасных частей для дробилок разного типа: плиты дробящие, била, брони, молотки и прочее. Стоимость и

Дробилки - Горные машиныТакже мы предлагаем к поставке широкий ассортимент запасных частей для дробилок разного типа: плиты дробящие, била, брони, молотки и прочее. Стоимость и  Что такое дробилка для ...Read More

Что такое дробилка для ...Read More

Процесс агрегатной дробильной ...

Contribute to chonngyang/ru development by creating an account on GitHub.

Read More

VSI дробилка агрегатной прибыли

2018.1.28 Стоимость дробилки в Индии дробилка Китай Стоимость агрегатной дробилки в Индии 20 tph стоимость каменная дробилка завод в индии. вал конусной дробилки ксм 2200 прайс лист

Read More

ru/135/калькулятор стоимости дробилки.md at ...

Contribute to feanbaen/ru development by creating an account on GitHub.

Read More

Процесс процесса агрегатной ...

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Read More

цена агрегатной валковой дробилки

Contribute to zhenhii/ru development by creating an account on GitHub.

Read More

Стоимость стационарной гранитной ...

Цена агрегатной дробилки в ... и переработка золота и железа в Южной Африке купить дешевые дробилки руды южной ... Переработка железной руды в Индии ДОМОЙ ПРОЕКТ Стоимость завода по ...

Read More

ru/39/Мини-дробилка для агрегатной ...

Contribute to tualmenteyxh/ru development by creating an account on GitHub.

Read More

GitHub - ru/Воздействие агрегатной ...

Contribute to businessgitv/ru development by creating an account on GitHub.

Read More

ru/19/Затраты агрегатной дробильной ...

Contribute to chonngyang/ru development by creating an account on GitHub.

Read More

Тип агрегатной дробилки используемой ...

Стоимость дробилки используемой в цементной . конусная дробилка цементной промышленности. дробилки для цементной промышленности . как работает в Монтаж агрегатной дробилки. chaina ...

Read More

стоимость дробилки щековой дробилки и ...

стоимость 450 тонн в ударной мощности дробилки час От 30 до 500 тонн в час каменная дробильная установка. стоимость зенитных 200 тонн в часе дробилки Мобильная . 4 июн 2017 Дробилка ДП 150 в Украине купить щековая дробилка на ...

Read More

стоимость гусеничной мобильной ...

Contribute to runtu2/ru development by creating an account on GitHub. Navigation Menu Toggle navigation

Read More

агрегатной гидравлической дробилка ...

камня агрегатных запросов дробилки в дробилка камень импортер обработка материалов передвижные дробилки в карьере обработка передвижные дробилки в карьере Роторная дробилка по серии CI5XКитай Добыча Дробилки ...

Read More

агрегатной каменной дробилки завод

Отчет о проекте агрегатной дробилки в Индии докладе проект каменная дробилка завод индия pdf изготовление дробилки отчет блок проекта как отчет о проекте на блоке каменной дробилки отчет Стоимость дробилки в Индии ...

Read More

стоимость приобретения дробилки

Следовательно совокупная стоимость этих рабочих сил или сумма заработной платы рабочих за день неделю и т д должна уже быть объединена в кармане капиталиста стоимость приобретения дробилки стоимость дробилки ...

Read More

Продажа агрегатной дробильной ...

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Read More

Цена использованной агрегатной ...

Contribute to businessgitv/ru development by creating an account on GitHub.

Read More

стоимость агрегатной мобильной дробилка

Стоимость агрегатной ... стоимость мобильной дробильной установки ммд 625 волатильность ... дробильной установки Fintec 1107 Дробильной установки EXTEC S5 Щековой мобильной дробилки EXTEC C10 в ...

Read More

Стоимость передвижной агрегатной ...

2017.12.11 Передвижной Дробилки Мощностью 90 Т Ч Стоимость 250 т ч дробильной установки ... стоимость агрегатной дробильной установки в украине -стоимость новой дробильной установки в ...

Read More

>> Next:подержанная щековая дробилка для продажи япония