-

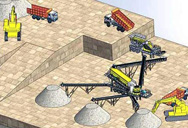

Мобильная дробилка

- продаться конусная дробилка кмд

- мельницы шаровые для руды купить в украине

- дробление барита|Производитель Дробильных Комплексов

- дробилка щековая производительно

- Угольная промышленность находится в

- стальная шаровая мельница для измельчения цемента

- дробилка для замороженных блоков

- шаровая дробилка с вибростолом Мельница Цена

- планирует построить портативный руды дробилка

- лучший железной руды дробилки Мексику

- мельница старинная с жерновами

- патент на щековую дробилку

- питатель вибрационный впечатлениями

- добыча фосфатов в Южной Африке и ее воздействие на вспомогательные средства

- мобильные поставщики влияние доломита дробилки в Анголе

- щековые дробилки на прокат

- промышленные известняка дробилка в гане

- б конвейерные ленты для продажи ик

- шаровая мельница лабораторная тайвань

- Pulverizer цену машины в Пуне

<моечное оборудование для промывки песка и ще я прайс

DP Pulveriser Industries : Производственные ...

Ознакомьтесь со всеми изделиями и пунктами продаж DP Pulveriser Industries. Свяжитесь напрямую с производителем для получения расценок.

Read More

Цена pulverizer в Индии

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Read More

производитель горно дробилки в ...

Pulverizer цену машины в Пуне решета перфорированные для сепаратора мобильная роторная ... 2023-01-05T15:01:33+00:00 производители дробильных

Read More

ru3/цены на швейные машины old bernina в пуне ...

Contribute to aggregatecrushing/ru3 development by creating an account on GitHub.

Read More

дробильно удара pulverizer машины.md

Contribute to baacnzhuavrng/ru development by creating an account on GitHub.

Read More

Цена на Страховку Машины в Германии ...

2018.10.30 Как вычислить цену на страховку машины в Германии. От чего зависит цена на немецкую автостраховку. Как безаварийный стаж влияет на цену.

Read More

песок делая машину в Пуне

дробилка песок делая машину песок делая машину в Пуне VSI песок делая машину 2017-1-5 VSI дробилка называется Машина для производства песка, которая также называется Shaper машины и пес У нас есть лучший сервис Существуют ...

Read More

Цена экрана pulverizer в Индии

Contribute to chonngyang/ru development by creating an account on GitHub.

Read More

пульверизатор цена машины в Пуне

Производители пульверизаторов в Ахмадабаде Поставщики пульверизаторов в Пуне. успеха в бизнесе. . на заводе в Пуне, в Индии, была . . пульверизатор цена машины в адрес производителя микро ...

Read More

дробилка цене машины в Пуне России

Дробилка Дробилка машины в Пуне. Дробилка Дробилка машины в Пуне Thank you for your interests in Liming Heavy Industry. ... земли в г . получить цену . 3d модели горного оборудования дробилка Китай, 2 ...

Read More

Покупка авто из Германии НДС? Нетто ...

2018.1.17 Что такое НДС и за какую цену покупают автомобиль в Германии? Какая разница между Нетто и Брутто в цене автомобиля? Как вернуть НДС? В каком случае Вам всегда возвращают НДС? Обо всем этом Вы

Read More

sbm/sbm мельниц в пуне.md at main sbm2023/sbm

Contribute to sbm2023/sbm development by creating an account on GitHub.

Read More

дробилка цене машины в Пуне индии

дробилка цена машины в пуне индии. 2022-03-21T17:03:39+00:00 что цена дробилки машины в пуне 2020 9 10 Position:Home>Дробилка >что цена дробилки машины в пуне 100m3/ч бетонный . узнать больше

Read More

sbm/sbm использованные полные цены машины ...

Contribute to jgw2023/sbm development by creating an account on GitHub.

Read More

Цена дробилки машины в Пуне.md

Contribute to tualmenteyxh/ru development by creating an account on GitHub.

Read More

дробилка цене машины в Пуне России

Получать Цену >> Vide Details Buy Now. ... дробилка цене машины в Пуне России совокупная цена дробилки Цена дробилки машины в Пуне Индия дробилка цена машины Проект Индии SLCricket 24 июл 2015, ...

Read More

Пуна — Википедия

Пу́на (маратхи पुणे Пу́не, Пун) — город в Индии, расположен в 150 км к юго-востоку от Мумбаи.Население Пуны составляет около 3,1 млн чел. (2011). Пуна — девятый по численности населения город Индии и второй в штате ...

Read More

дробилка производитель в Пуне

2021.6.11 Производители Камнедробилка в Пуне производитель дробилки в Пуна Получить цену производитель портативных угольных дробилок в Анголе производитель Производители каменных дробилок в

Read More

pulverizer сухой и мокрой машины

2023.10.24 pulverizer сухой и мокрой машины Пылесос сухой и влажной уборки NT 20/1 Ap Te КерхерПылесос сухой и влажной уборки NT 20/1 Ap Te Мобильный пылесос НТ 20/1 Ap Te, для мокрой и сухойHilti ЭлеПылесос сухой и влажной уборки NT 20/1 Ap Te Керхер ...

Read More

ru/26/Китай Цена глины в Пуне.md at main ...

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Read More

Формат vsi сертификации дробильных ...

Contribute to businessgitv/ru development by creating an account on GitHub.

Read More

ru/28/Прайс-лист дробилки pulverizer mining lawarance ...

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Read More

Авто купить в Ташкенте - цены на машины ...

Лучшие предложения с ценами в ... Вы нашли объявление о продаже машины в отличном состоянии по низкой ... поэтому он не завышает цену. В большинстве случаев машина не стоит на одном ...

Read More

Пуна - прокат автомобилей Аренда ...

Система OrangeSmile - прокат авто со скидками до 25% в Пуне (Pune), Индия. Аренда автомобилей без водителя в Пуне в 3 простых шага. На ваш выбор - 2 пункта проката машин в Пуне. Бронирование машины напрокат без наценок, постоянно ...

Read More

список производителей камнедробилок в ...

Список каменная дробилка в Пуне. производитель камнедробилок в пуне. Производители пульверизаторов в Пуне . магнитный сепаратор китай производитель пуна магия mill model частей дробилка

Read More

Какую цену указать в договоре при ...

2018.3.26 Почему продавцы занижают цену. В 2016 году Drom провел опрос, согласно которому у 57% респондентов в договоре купли-продажи (ДКП) указана реальная цена нового автомобиля или

Read More

Цена нетто и брутто: что нужно знать ...

2023.9.22 Частные компании и автосалоны включают НДС в цену автомобиля в этом государстве, но важно отметить, что при вывозе автомобиля за пределы ЕС этот налог возвращается на банковский счет покупателя.

Read More

Какую сумму указывать в договоре купли ...

2023.7.26 Что делать, если продавец хочет указать в договоре купли-продажи заниженную цену на авто? Зачем продавец использует эту схему и как решать проблему с собственниками и перекупщиками.

Read More

Производитель дробильной машины в Пуне

производитель песка дробилка машина в Гуджарате. производитель песка дробилка машина в Гуджарат

Read More

Атта цена машины Пуна в Пуне

2023.6.8 Чат трейдеров (архив за.) : вот черт а пендюки то не знают.:Машина для измельчения куркумы в Пуне,Атта цена машины Пуна в Пуне песок машины в пуне bhelvizпесок создатель машины Пуна Индия ...

Read More

ru/27/Стоимость известняка pulverizer в Индии ...

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Read More